Introduction

Brief introduction:

floating metal seal ball valve have the features such as small fluid resistance, smooth flow, open and close quickly, easy to auto-control, so they have been used widely. The normal ball valves in general adopt PTFE such as non-metal material, it can not be used in high temperature conditions and some

medium contains solid grains, cinder etc, so the normal ball valves are restricted partially. For this reason, our company has developed full range of metal to metal sealed ball valve, including floating ball valve and trunnion ball valve successfully after years of hard work, which have obtained wide applications in petroleum, chemical, power, metallurgy and light industry etc.

Except for such features as misoperation prevention, blow-out proof stem, the platform for actuator installation, the metal to metal sealed ball valves possess the following unique features:

Metal to metal sealed design has been employed perfectly for the ball and seat, which has also adopted the advanced hardening technologies, such as ultro-sonic spray coating, nickel base spray welding, surface specially hardening, stellite spray welding, ceramic material with high strength and hardness and so on. Surface hardness of the ball and seat may generally reach more than HRC60, maximun is up to HRC74, and application temperature of the material may be up to 540 C, maximun is 980 C. Combining strength of the material gets to more than 10000 PSI. Besides, the surface materials also possess very good resistance properties of friction and impact. Our metal to metal sealed ball valves are suitable for most of critical working conditions.

In the case of high temperature working condition, the valve seat and ball would easily get stuck due to heat expansion, and the valve could not be open. Metal to metal sealed ball valves made by employed the patented design of bevelling spring loading, which would absorb the heat expansion of parts caused by the bevelling spring. So it is ensured that the valve would not get stuck and be opened and closed easily in the case of high temperature condition.

Excellent tightness function

Complete fire-safe structure

Natural anti-static structure

Double block and bleed function

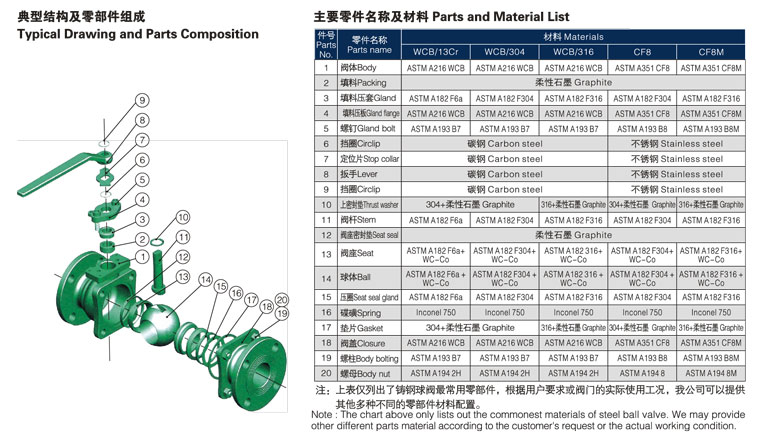

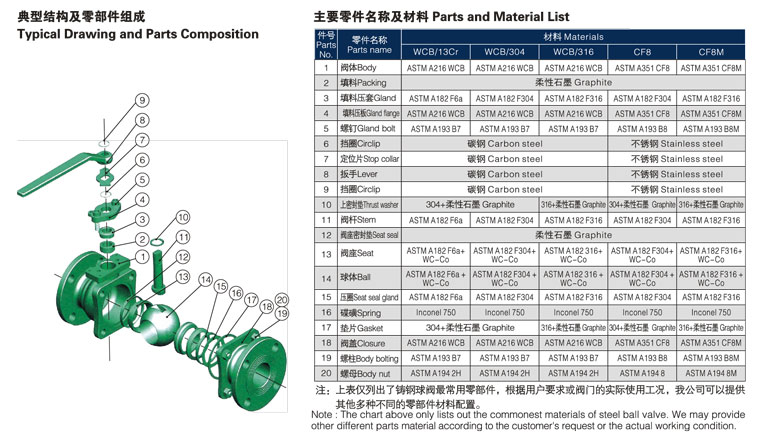

Structural drawing and the material of main parts:

Notes: Please refer to floating ball valve for main dimensions and weights of metal to metal sealed floating ball valve. The flange dimensions and face to face dimensions are the same as soft sealed floating ball valve.